Jetter control systems

NANO

JC-24x

JetMove D203

JC-3xx

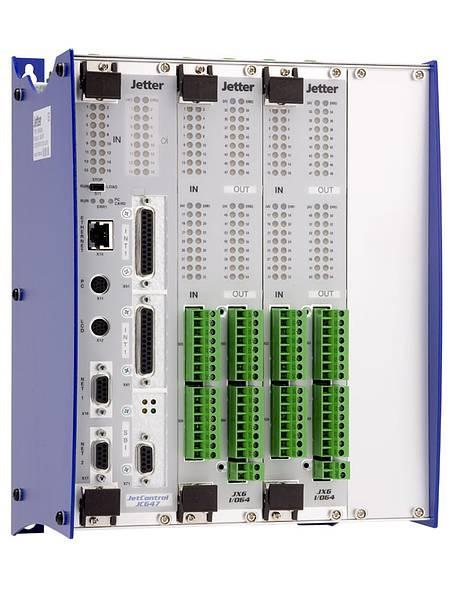

JC-647

JC-9xx

Technical data:

| Processor | 1.86 GHz Celeron (fanless) |

| Memory | 1024 MB SD-RAM, 512 KB residual RAM, CF card (to replace hard disk) |

| Connectors | 3xEthernet, 4xUSB, RS232, CAN |

| Power supply | 24V DC |

| Dimensions (W x H x D) | 77x310x242mm |

| Order number | 10000742 JC-940MC |

The NANO control family in the compact size class is excellently suited for classic automation tasks. Scalable CPU performance and modules from the JX2 series make these controllers versatile. NANO controls are particularly suitable for small and medium tasks. But they are also excellent for network operation, which makes larger, distributed tasks possible. The extension modules of the JX2 series offer all essential automation functions, from digital inputs and outputs to various positioning functions.

- Modular small controllers with various performances

- From simple I/O applications to 4 servo axis applications

- High-level programming, multitasking program execution

- All functions in the device: control, management, positioning, display, data management

NANO-A

| Usable register integer 24 bits | 250 (200 non-retentive; 50 EEPROM) |

| Program container | 6KB EEPROM |

| Floating-point user register | – |

| Integer register format | 24 bits |

| Dig. in. on the base device | 8 |

| Dig. who. on the base device | 6 |

| An. in. on the base device | – |

| An. who. on the base device | – |

| Stepper motor driver. on the base device | – |

| Real Time Clock | None |

| 1 buckle. counter on the base device | 10 kHz |

| Connectors | 1xRS232/RS485, 1xRS232/RS422 |

| Dimensions (WxMaxD) | 110x114x70mm |

| Max JX2 module number | 5 |

| Max slave module number | – |

| Extensible | JX2, LJX-7, LioN-S, Smart I/O, CANopen |

NANO-B

| Usable register integer 24 bits | 2000 battery protected RAM |

| Program container | 16KB EEPROM |

| Floating-point user register | – |

| Integer register format | 24 bits |

| Dig. in. on the base device | 8 |

| Dig. who. on the base device | 6 |

| An. in. on the base device | 4 (10 bits, 0-10V) |

| An. who. on the base device | 1 (8 bits, 0-10V) |

| Stepper motor driver. on the base device | 1 (STEP, DIR) |

| Real Time Clock | There is |

| 1 buckle. counter on the base device | 10 kHz |

| 2 buckles. counter on the base device | 10 kHz |

| Connectors | 1xRS232/RS485, 1xRS232/RS422 |

| Dimensions (WxMaxD) | 110x114x70mm |

| Max JX2 module number | 15 |

| Max slave module number | 3 |

| Extensible | JX2, LJX-7, Smart I/O, CANopen |

NANO-C

| Usable register integer 24 bits | 10000 battery protected RAM |

| Program container | 64KB EEPROM |

| Floating-point user register | 256 |

| Integer register format | 24 bits |

| Dig. in. on the base device | 8 |

| Dig. who. on the base device | 6 |

| An. in. on the base device | 4 (10 bits, 0-10V) |

| An. who. on the base device | 1 (8 bits, 0-10V) |

| Stepper motor driver. on the base device | 1 (STEP, DIR) |

| Real Time Clock | There is |

| 1 buckle. counter on the base device | 10 kHz |

| 2 buckles. counter on the base device | 10 kHz |

| Connectors | 1xRS232/RS485, 1xRS232/485/422 |

| Dimensions (WxMaxD) | 110x114x70mm |

| Max JX2 module number | 15 |

| Max slave module number | 3 |

| Extensible | JX2, LJX-7, Smart I/O, CANopen |

NANO-D

| Usable register integer 24 bits | 32000 battery protected RAM |

| Program container | 64KB EEPROM |

| Floating-point user register | 256 |

| Integer register format | 24 bits |

| Dig. in. on the base device | 8 |

| Dig. who. on the base device | 6 |

| An. in. on the base device | 4 (10 bits, 0-10V) |

| An. who. on the base device | 1 (8 bits, 0-10V) |

| Stepper motor driver. on the base device | 1 (STEP, DIR) |

| Real Time Clock | There is |

| 1 buckle. counter on the base device | 10 kHz |

| 2 buckles. counter on the base device | 10 kHz |

| Connectors | 1xRS232/RS485, 1xRS232/485/422 |

| Dimensions (WxMaxD) | 110x114x70mm |

| Max JX2 module number | 23 |

| Max slave module number | 4 |

| Extensible | JX2, LJX-7, Smart I/O, CANopen |

The JC-24x control family was specially developed for use in distributed, segmented systems in industrial environments. Ethernet uses TCP/IP as a connection medium, thus creating an interoperable connection to the IT levels (maintenance and management level). The modular structure is ideal for tailor-made automation solutions.

- For compact equipment with up to 8 servo axes

- Modular construction

- High level programming (ST/STX)

- Ethernet TCP/IP communication, i.e.: browser display, remote maintenance, email sending, database access

JC-241

| Memory (Flashdisk) | 1 MB |

| Registry (protected) | 30000 Integer or floating point |

| Program container | 64KB |

| Dig. in. on the base device | 16 |

| Dig. who. on the base device | 8 |

| Connectors | Ethernet (10/100 Mbit), 1xRS232/422 |

| Dimensions (WxMaxD) | 156x115x58mm |

| Max JX2/JX3 module number | 7 |

| Max slave module number | 1 |

| Extensible | JX2, JX3, LJX-7, LioN-S, Smart I/O, CANopen |

| Real Time Clock | There is |

| Integrated Web Server | Optional |

| Send email | Optional |

| Modbus TCP | Optional |

| Ethernet IP | Optional |

JC-243

| Memory (Flashdisk) | 3 MB |

| Registry (protected) | 30000 Integer or floating point |

| Program container | 64KB |

| Dig. in. on the base device | 16 |

| Dig. who. on the base device | 8 |

| Connectors | Ethernet (10/100 Mbit), 2xRS232/422 |

| Dimensions (WxMaxD) | 156x115x58mm |

| Max JX2/JX3 module number | 15 |

| Max slave module number | 3 |

| Extensible | JX2, JX3, LJX-7, LioN-S, Smart I/O, CANopen |

| Real Time Clock | There is |

| Integrated Web Server | Optional |

| Send email | Optional |

| Modbus TCP | Optional |

| Ethernet IP | Optional |

JC-246

| Memory (Flashdisk) | 7MB |

| Registry (protected) | 30000 Integer or floating point |

| Program container | 64KB |

| Dig. in. on the base device | 16 |

| Dig. who. on the base device | 8 |

| Connectors | Ethernet (10/100 Mbit), 2xRS232/422 |

| Dimensions (WxMaxD) | 156x115x58mm |

| Max JX2/JX3 module number | 23 |

| Max slave module number | 6 |

| Extensible | JX2, JX3, LJX-7, LioN-S, Smart I/O, CANopen |

| Real Time Clock | There is |

| Integrated Web Server | Optional |

| Send email | Optional |

| Modbus TCP | Optional |

| Ethernet IP | Optional |

JC-248

| Memory (Flashdisk) | 7MB |

| Registry (protected) | 30000 Integer or floating point |

| Program container | 64KB |

| Dig. in. on the base device | 16 |

| Dig. who. on the base device | 8 |

| Connectors | Ethernet (10/100 Mbit), 2xRS232/422 |

| Dimensions (WxMaxD) | 156x115x58mm |

| Max JX2/JX3 module number | 31 |

| Max slave module number | 8 |

| Extensible | JX2, JX3, LJX-7, LioN-S, Smart I/O, CANopen |

| Real Time Clock | There is |

| Integrated Web Server | Optional |

| Send email | Optional |

| Modbus TCP | Optional |

| Ethernet IP | Optional |

The JetMove D203 is a really compact dual-axis servo amplifier. Thus, two independent axes can be connected to one control via the system bus. The tool offers many options. Among other things, it can be equipped with integrated control (JC-24x as an option) and thus becomes an unsurpassed compact device with integrated control and 2 full servo controllers. The double-axis amplifier is designed for the 1 kW (continuous) power range and requires a direct 1x230V AC power supply.

Due to its unique integration into the control system, it stands out from traditional devices and wins over users with its versatility and simplicity. Due to the integration with the control system, commissioning times and maintenance work are reduced to a minimum. The available technological and special functions enable the greatest possible flexibility and functionality.

- The easiest handling and quick commissioning

- Many options

- Integrated technological and special functions

- Control of different motor versions: synchronous and asynchronous motors, 3-phase stepping motors, direct drives, etc.

Options:

- Integrated web server for remote access

- Ethernet connector for the factory (manufacturer) network connection

- Control panel connection option

- Freely programmable serial port

- Data storage or data exchange with an integrated SD card reader

- Connection of decentralized peripherals

- Control and drive of two motors (synchronous motors, asynchronous motors, stepper motors, linear motors)

- “Safety stop” function

- Further fieldbus connectors are available, e.g.: Profibus DP, DeviceNet

JetMove D203

| Network Connection | 1 Phase |

| Rated voltage (Ueff) | 230V AC |

| Operating voltage (Ueff) | 195-265V AC |

| Input Frequency | 48-62 Hz |

| Network filter | Integrated |

| Rated current (Ieff) | 2×3 A |

| Peak current (Ieff) | 2×6 A |

| Sustained performance | 2×0.5 kW |

| Connectors | Jetter System Bus / Ethernet (optional) |

| Dimensions (WxMaxD) | 87x310x203mm |

The compact form together with the JX3 expansion modules offer the highest performance in a small space and thus support the increased requirements in the construction of the switch cabinet.</p >

- From cost-effective entry-level solutions to high-end controls with motion control

- Unlimited number of servo axes (up to max. 16 CAN drives)

- Up to 12 servo-axis trajectory control

- Network connection via an integrated switch

- High-performance JetSym STX development environment (multitasking operation)

- Easy service due to pluggable connectors and modular construction

- Performance can be easily increased by replacing the CPU

JC-340

| Retentive register | 2000 |

| Program/Repository | 1 MB |

| Number of pluggable modules | 16 |

| Number of Drives | 0 or 3 |

| Number of Motion Control drives (track control) | – |

| Connectors | 1 serial port (RS232/422/485), 1 system bus (CAN), 2 Ethernet ports, integrated switch |

| SD card slot | Optional |

| Dimensions (MaxHxW) | 131x100x50mm |

| Extensible | JX2, JX3, LJX-7, Lion-S, Smart I/O, CANopen |

| Real Time Clock | There is |

| Integrated Web Server | Optional |

| Send email | Optional |

| Modbus TCP | Optional |

JC-350

| Retentive register | 6000 |

| Program/Repository | 2 MB |

| Number of pluggable modules | 16 |

| Number of Drives | 4 or 8 |

| Number of Motion Control drives (track control) | – |

| Connectors | 1 serial port (RS232/422/485), 1 system bus (CAN), 2 Ethernet ports, integrated switch |

| SD card slot | Built-in |

| Dimensions (MaxHxW) | 131x100x50mm |

| Extensible | JX2, JX3, LJX-7, Lion-S, Smart I/O, CANopen |

| Real Time Clock | There is |

| Integrated Web Server | Optional |

| Send email | Optional |

| Modbus TCP | Optional |

JC-360

| Retentive register | 60000 |

| Program/Repository | 4MB |

| Number of pluggable modules | 16 |

| Number of Drives | 4, 8, unlimited (max. 16 CAN drives) |

| Number of Motion Control drives (track control) | max. 12 |

| Connectors | 1 serial port (RS232/422/485), 1 system bus (CAN), 2 Ethernet ports, integrated switch |

| SD card slot | Optional |

| Dimensions (MaxHxW) | 131x100x50mm |

| Extensible | JX2, JX3, LJX-7, Lion-S, Smart I/O, CANopen |

| Real Time Clock | There is |

| Integrated Web Server | There is |

| Send email | There is |

| Modbus TCP | There is |

The JC-647 is a powerful high-end controller. The outstanding scalability and connectivity options enable the implementation of all automation tasks in the modern industrial world. In addition to classic control functions, Motion-Control also offers the additional option of programming axis connections and complex path movements. Special attention was paid to the simple and efficient realization of complex track controls. With the JetSym STX environment, programming and commissioning costs can be reduced to a minimum.

- High-end control with Motion Control

- Up to 24 servo axes

- Modular construction

- High level programming (ST/STX)

- Motion-Control

- Ethernet TCP/IP communication, i.e.: browser display, remote maintenance, email sending, database access

JC-647

| Data container | 480000 registers, 32 bits |

| Program container | 256KB |

| Motion Control track control | There is |

| Connectors | Ethernet 10/100 BaseT, 1xRS232, 2xRS485, 1xRS232/485/422 |

| Dig. in. on the base device | 16 |

| Dimensions (WxMaxD) | 73x310x205mm |

| Max servo axis number | 24 |

| Extensible | JX2, JX3, LJX-7, Lion-S, Smart I/O, CANopen |

| Real Time Clock | There is |

| Integrated Web Server | There is |

| Send email | There is |

| Modbus TCP | Optional |

| Ethernet IP | Optional |

Deutsch

Deutsch Magyar

Magyar